The top portion of the column contains the spindle. The basic function of the over-arm is to support the arbor and spindle. Overarm is present at the top of the column. A table can travel longitudinally in a horizontal plane. The table consists of T-slots or sometimes fixtures are used for holding up the workpiece on the table. The table is present on the top of the saddle. Its basic function is to support the table.Ī saddle can slide on the guideways which are exactly at 90 degrees to the column face. Saddle moves crosswise(in or out) on guideways provided on the knee. The saddle is present on the top of the knee which further carries the table. It is attached to the column and has guideways by which it can move up and down with the help of the elevating screw for adjusting its height. This is an important part of this machine that supports the other parts like the saddle and table. The knee shape is quite similar to that of the human body knee. The driving mechanism usually consists of a cone pulley mechanism in which the v-belt is being used to connect it to the motor.įurther by using this driving mechanism the speed of the machine can control as per our requirement. The main supporting frame which consists of all the driving mechanisms and the motor is called the column. Cutting fluid can also be stored in the base. It also helps in the absorption of shocks. The base is mostly made up of cast iron, so it has good strength and rigidity. It is a type of foundation for the machine. The base is the part upon which the whole machine parts are being mounted. It is very accurate and has a high production speed Gradually with time now we have the most advanced form of the Milling machine which is the CNC Milling Machine. Now, these machines can perform multiple operations. Later he developed a semi-automatic Milling machine which further enhanced the production. Eli Whitney got a big order from the government for the production of Musket. Inventor name: Eli Whitney invented the Milling machine in the year 1818.ĭuring that time, it was used for the making of gun parts. This was the better-developed form of the Milling machine. Then in the 18th century in the united states, a machine was used which was similar to the lathe machine but in this machine, The cutting tool is used to rotate and the workpiece uses to remain stationary. It was used by the clockmakers at that time.

The milling machine is believed to come into existence in 17 the century. Milling Machine disadvantages with remedies:.From start to finish of the cut it does not makes noise and operates smoothly. The main advantages of this machine the cutting speed and force of the ram drive are constant. The high-pressure oil first acts on one side of the piston and then on the other causing the piston to reciprocating and the motion is transmitted to the ram. This Hydraulic shaper uses the oil under high pressure and the end of the piston rod is connected to the ram. In this type of machine, the reciprocating motion of the ram is provided by the hydraulic mechanism. In this machine, the workpiece metal is removed during the return stroke of the Ram. The tool (Single Point) is reciprocating in motion equal to the length of the stroke and the work is clamped in position on an adjustable table. This universal features enables to perform various types of operations on this machine. In this type of machine, you can also swivel the table about its own axis. Either horizontally, vertically or an inclined plane. The major advantages of Universal shaper is that, you can feed the table in all directions. The feed or depth of cut of the tool is given by down feed screw.

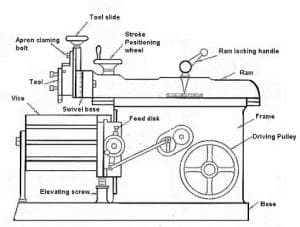

The tool head is in the clapper box, which causes cutting action only in a forward stroke of the ram. The Ram reciprocates and it carries the tool head in which single point cutting tool is attached. The vertical movement and Horizontal movement is given to the table by raising or lowering the cross rail using the elevating screw and by moving the saddle using the cross feed screw. It is also mounted on the column on which the saddle is mounted. In heavier type shaper machines, the table clamped with table support to make it more rigid. These surfaces having T-Slots for clamping the work. It is a box-like casting with an accurately machined side and top surfaces. The table can be moved crosswise by rotating the crossfeed rod and also for vertical by rotating the elevating screw. It is also one of the important parts of the machine. It also acts for covering the drive mechanism. Column supports the ram that is moving forward and backward for operation. It absorbs vibration and other forces that occur while performing shaping operations. The base is the most important part of the shaper because it holds all the loads of the machine.

0 kommentar(er)

0 kommentar(er)